This week we’ve got lots to shout about. We’ve got a new leather, a new style and a new construction, all in our latest shoe launch! We’ve been talking a lot about leather this year and as our materials lead our design, a new leather means new ideas, projects and plans.

We have been toying with the idea of creating a casual sneaker for the warmer seasons, even more pared back but sticking to our minimal design aesthetic and emphasis on using the best materials we can source. We have a variety of colours on the way so please keep your eyes peeled for new arrivals. If you want any updates on this or any of our other products join the mailing list here.

We’ve got our hands on Horween's ‘Dearborn’ leather and it’s led to us working on a new sneaker to sit in our Hand Stitch Collection.

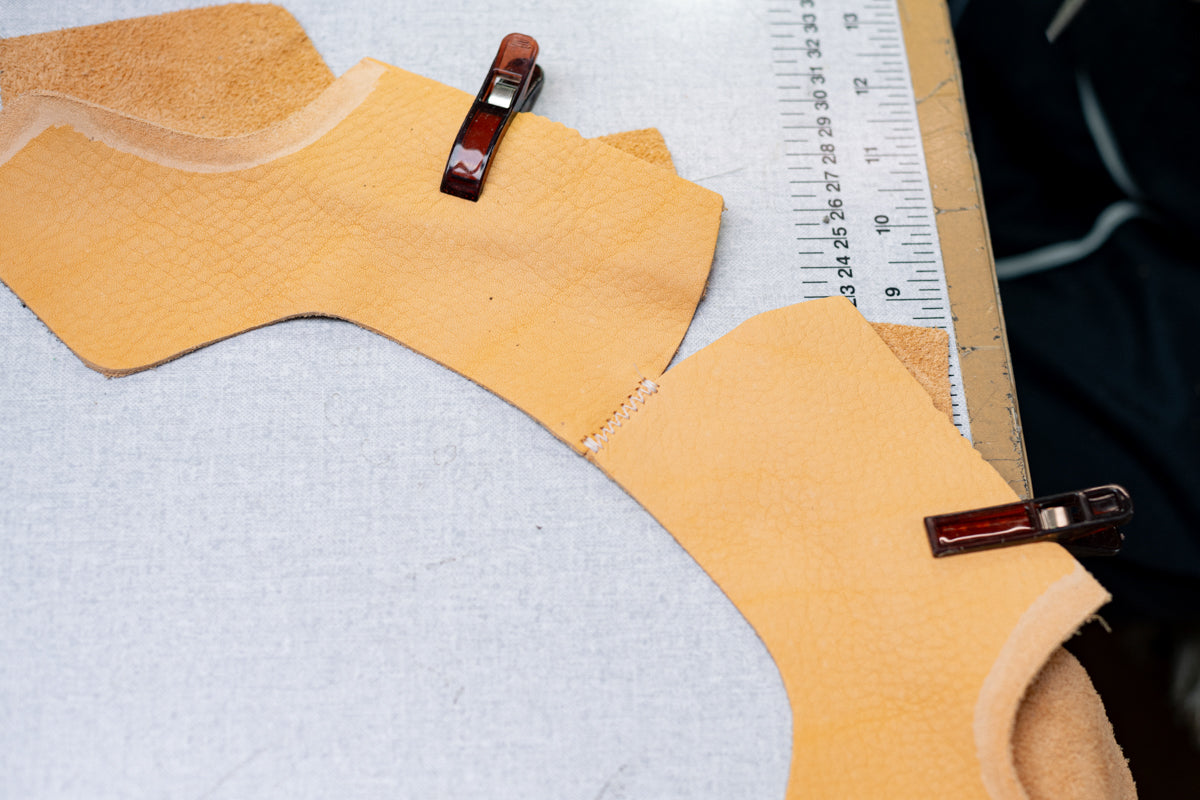

Examining Dearborn variations across the skin to get matched pairs. The uneven grain means that every pair is unique

Examining Dearborn variations across the skin to get matched pairs. The uneven grain means that every pair is uniqueInspired by the leather, Chris designed an unlined sneaker with some very special touches beneath the surface.

Our designs are guided by our materials here at Crown Northampton. We start with the leathers and then find ways of using its unique character, figuring out what it technically allows us to do, all using old traditional Northampton shoe making techniques while staying true to our primary design ethos; every stitch serves a purpose.

A memory from the past served as inspiration for the future.

25 years ago, Chris and his father, Andy, visited a factory in Northampton called Haynes & Cann to buy a leather splitting machine. To demonstrate the use of the machine, the operative picked up some heavy weight calf leather, which was used for their RAF boots and fed it into the machine to reduce its thickness. As the blade reached halfway through splicing the leather, the operative pulled it back out of the machine which Chris had not seen done before. The reason for this was to insert the toe puff inside the leather, negating the need for a lining. This unusual technique was logged in Chris’ mind until it could be put to use. Fast forward to April 2024, and this method has found its way into Crown Northampton’s Abbey Unlined Sneaker.

Split quarters and vamp with structure insertion

Split quarters and vamp with structure insertion

Zigged, skived and split quarters, pegged for the next stage of production

Zigged, skived and split quarters, pegged for the next stage of production Oak bark collar inserted, pegs to be removed to hide it

Oak bark collar inserted, pegs to be removed to hide it French binding being machined on before hand folding

French binding being machined on before hand folding Reinforced backstrip being attached

Reinforced backstrip being attached Beaded vamp being attached to quarters

Beaded vamp being attached to quarters Hand stitching tongue in place with split tongue to cover stitching

Hand stitching tongue in place with split tongue to cover stitching Hand Stitching finish

Hand Stitching finishWe never force the design of any of our products, the final product is always a few adaptations from the original. Chris begins the design process, pattern cuts and refines the shoe’s construction in collaboration with our team on the factory floor. The design and structure is always adapted based on the advice of the people working on it.

In the end, the Abbey Unlined Sneaker has evolved into a traditional 5 eyelet Oxford, French bound, with a hand stitched tongue.

Horween Dearborn - Not typically a leather for shoes, until now.

Dearborn is a thick, vegetable tanned leather with a luxuriously soft feel on both sides of the hide. This makes it perfect for an unlined sneaker as the leather can comfortably sit directly against the foot. It’s a high-quality cattle leather, designed to have the feel of deer skin with the strength, resilience and durability of cow skin.

The reverse: Part of the reason for choosing Dearborn was how soft the reverse is

The reverse: Part of the reason for choosing Dearborn was how soft the reverse is

We felt this quality of leather would sit comfortably among the other premium materials that make up our Hand Stitch Collection. Inside our Hand Stitch Collection sneakers, we use J&FJ Baker’s pit tanned calf leather for structure and strength, cork for the midsole and this collection’s signature Lactae Hevea sole unit. The binding leather for the Abbey sneaker is also Dearborn, so it matches the upper perfectly and is split so it’s the ideal thickness to fold over the top line and keep things neat.

All the components used in just half a pair of Dearborn sneakers

All the components used in just half a pair of Dearborn sneakers

Quarters of a natural Dearborn sneaker with its oak bark collar

Quarters of a natural Dearborn sneaker with its oak bark collar

The concealed skeleton structure we have used in order to give the sneaker its shape utilises Baker’s oak bark tanned English calf.

Leather: Baker’s Oak Bark shoulder examination before insoles are cut

We have selected the shoulder for its strength and durability and it’s often used by our hand-welted sister company, E. Woodford. A band of this leather runs from the front of the quarters around the topline and down the back strip.

The toe puff is baby calf, split to 1mm thickness and inserted in the upper leather in a manner that compliments the soft feel of Dearborn, so that there aren’t any hard ridges sitting against the foot. Once wetted, the toe puff sets and moulds to the shape of the last.

Our insole is Baker’s oak bark tanned English calf shoulder too, split to 4mm. It’s softened to allow the sneaker to flex and mould to the shape of the foot. When used in combination with the cork midsole filler and Lactae Hevea sole, it leaves the shoe feeling slipper soft and uniquely moulded to the wearer’s foot.

We want to be proud of the footwear we produce so we go to great lengths to source the finest materials available, ensuring that each pair is the best we can make. All of the above processes and the combination of construction techniques and skills results in a super comfortable, lightweight, durable and still minimal shoe style. Perfectly suited to casual styling during the warmer months, they work with or without socks and will only get better and more comfortable with every wear.

We can’t wait to see what you think and experience how they feel on your feet.